Inside Pharma's Manufacturing Revolution: The Strategic Shifts Reshaping Global Production

Companies

2025-04-11 07:13:22Content

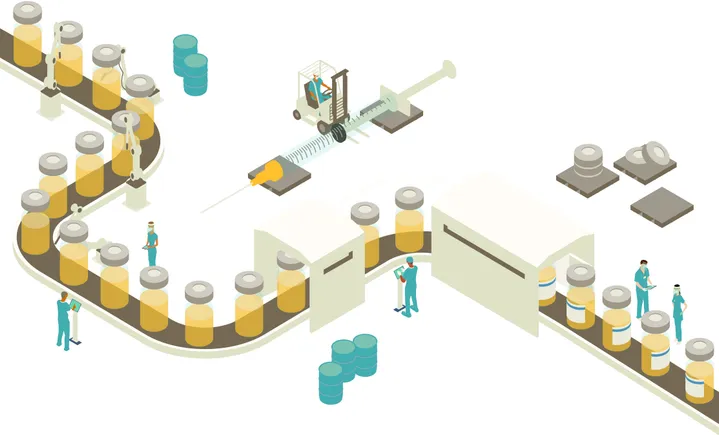

As global trade tensions escalate, the ongoing tariff war is sparking a significant shift in manufacturing strategies. Pharmaceutical giants are leading the charge, increasingly bringing production back to domestic shores in a trend known as reshoring.

The complex geopolitical landscape has exposed vulnerabilities in global supply chains, compelling major pharmaceutical companies to reconsider their international manufacturing footprints. By localizing production, these firms aim to reduce risks, enhance supply chain resilience, and mitigate potential disruptions caused by ongoing trade conflicts.

This strategic pivot not only addresses immediate economic challenges but also represents a broader movement towards creating more robust and self-sufficient domestic manufacturing ecosystems. As companies reassess their global production networks, reshoring is emerging as a critical strategy for maintaining competitive advantage and ensuring long-term operational stability.

Manufacturing Revolution: How Global Trade Tensions Are Reshaping Pharmaceutical Production

In an era of unprecedented global economic uncertainty, the pharmaceutical industry stands at a critical crossroads. The complex interplay of geopolitical tensions, trade wars, and supply chain vulnerabilities has triggered a profound transformation in how pharmaceutical companies approach manufacturing strategies.Breaking Barriers: The Urgent Call for Domestic Manufacturing Resilience

The Geopolitical Landscape of Pharmaceutical Manufacturing

The contemporary pharmaceutical landscape is experiencing a seismic shift driven by escalating international trade tensions. Multinational corporations are increasingly recognizing the strategic imperative of reshoring manufacturing capabilities, moving away from traditional offshore production models. This transformation is not merely an economic strategy but a critical response to systemic vulnerabilities exposed during recent global disruptions. Pharmaceutical giants are now investing heavily in domestic manufacturing infrastructure, viewing it as a strategic necessity rather than an optional approach. The complex calculus of global trade has fundamentally altered corporate decision-making, compelling organizations to prioritize supply chain resilience and national economic security.Economic and Strategic Implications of Reshoring

Reshoring pharmaceutical manufacturing represents a multifaceted strategic initiative with profound economic implications. By establishing domestic production facilities, companies can mitigate risks associated with international supply chain disruptions, reduce dependency on foreign manufacturing ecosystems, and create significant domestic employment opportunities. The economic calculus extends beyond immediate production considerations. Companies are discovering that localized manufacturing can provide enhanced quality control, faster market responsiveness, and greater flexibility in adapting to rapidly evolving regulatory environments. This approach represents a sophisticated risk management strategy that balances economic efficiency with national strategic interests.Technological Innovation and Manufacturing Transformation

The reshoring movement is intrinsically linked to technological innovation. Advanced manufacturing technologies such as artificial intelligence, robotics, and precision engineering are revolutionizing pharmaceutical production processes. These technologies enable more efficient, cost-effective, and scalable domestic manufacturing capabilities. Pharmaceutical companies are investing in cutting-edge research and development infrastructure, creating sophisticated manufacturing ecosystems that leverage automation, data analytics, and advanced materials science. This technological renaissance is not just transforming production methodologies but fundamentally reimagining the entire pharmaceutical manufacturing paradigm.Regulatory and Policy Dynamics

Government policies and regulatory frameworks are playing a crucial role in facilitating the reshoring of pharmaceutical manufacturing. Policymakers are implementing strategic incentives, tax benefits, and supportive regulatory environments to encourage domestic production capabilities. These policy interventions reflect a broader recognition of the strategic importance of maintaining robust domestic pharmaceutical manufacturing infrastructure. By creating conducive economic conditions, governments are actively participating in reshaping the global pharmaceutical production landscape.Global Competitive Dynamics

The reshoring trend is fundamentally altering global competitive dynamics within the pharmaceutical industry. Companies that successfully implement domestic manufacturing strategies are gaining significant competitive advantages, demonstrating enhanced agility, resilience, and strategic positioning. This transformation extends beyond individual corporate strategies, representing a broader systemic shift in how pharmaceutical companies conceptualize production, innovation, and global market engagement. The ability to rapidly adapt and localize manufacturing capabilities is becoming a critical determinant of long-term success in an increasingly complex global economic environment.RELATED NEWS

Companies

Toxic Seafood Alert: California's Landmark Settlement Reveals Safe Eating Strategies

2025-04-29 23:37:06

Companies

Breaking Barriers: How Camb.ai is Revolutionizing Sports Content Localization

2025-02-24 11:00:00