Trade War Fallout: Local Hardware Shop Braces for Economic Tsunami Under Trump Tariffs

Business

2025-04-08 06:25:11Content

In the heart of San Francisco, a local hardware store owner reveals a stark reality of modern retail: nearly 80% of the products lining his shelves are manufactured overseas, with China dominating the production landscape. This revelation highlights the complex global supply chain that has transformed the way American businesses source their merchandise.

The store owner's experience reflects a broader trend in the retail industry, where international manufacturing has become the norm rather than the exception. Chinese production capabilities have revolutionized how hardware and consumer goods are created and distributed, offering cost-effective solutions that have reshaped local business inventories across the United States.

From tools and fixtures to household hardware, the global marketplace has fundamentally altered the traditional concept of "Made in America," presenting both challenges and opportunities for small business owners navigating an increasingly interconnected world.

Global Manufacturing Shift: The Untold Story of American Retail's Dependence on International Production

In the heart of San Francisco's bustling retail landscape, a profound economic narrative is unfolding—one that reveals the intricate web of global manufacturing and its profound impact on local businesses. The story of one hardware store owner serves as a microcosm of a larger economic transformation that is reshaping the American retail ecosystem.Unveiling the Global Manufacturing Paradigm: When Local Meets Global

The Changing Landscape of Retail Manufacturing

The contemporary retail environment represents a complex tapestry of international economic interactions. Hardware stores, once bastions of local manufacturing pride, now find themselves navigating a global marketplace where production capabilities have dramatically shifted. The traditional narrative of American manufacturing dominance has been fundamentally challenged by emerging economic powerhouses, particularly China, which has revolutionized industrial production strategies. Retailers are confronting an unprecedented economic reality where cost-effectiveness and manufacturing efficiency have become paramount. The globalization of supply chains has transformed how businesses source their products, creating intricate networks that span continents and challenge traditional economic boundaries.Economic Implications of International Production

The proliferation of international manufacturing represents more than a simple economic trend—it's a fundamental restructuring of global economic dynamics. For small business owners like our San Francisco hardware store proprietor, this shift means adapting to a marketplace where 80 percent of inventory originates from overseas manufacturers. This dramatic transformation isn't merely about price points; it reflects profound changes in technological capabilities, labor markets, and global economic strategies. Chinese manufacturers have developed sophisticated production techniques that allow them to create high-quality products at significantly reduced costs, fundamentally altering competitive landscapes across multiple industries.The Human Cost of Global Manufacturing Shifts

Behind every imported product lies a complex narrative of economic adaptation and human labor. The transition from local to global manufacturing isn't just an abstract economic concept—it represents real-world implications for workers, businesses, and entire communities. Small business owners find themselves at the intersection of these massive economic shifts, forced to make strategic decisions that balance economic survival with maintaining product quality and competitive pricing. The hardware store becomes more than a retail space; it transforms into a microcosm reflecting broader economic transformations.Technological Innovation and Global Production

Technological advancements have been instrumental in enabling this global manufacturing revolution. Precision engineering, automated production lines, and sophisticated supply chain management have allowed countries like China to become global manufacturing leaders. These technological capabilities extend far beyond simple cost reduction. They represent a holistic approach to production that integrates design, engineering, and manufacturing into seamless processes that can rapidly respond to market demands and technological innovations.Future Perspectives: Navigating the Global Manufacturing Ecosystem

As businesses continue to adapt to these dynamic economic landscapes, the future of retail and manufacturing remains fluid and complex. The narrative is no longer about national manufacturing pride but about creating adaptive, flexible business models that can thrive in a globally interconnected economic environment. For retailers like our San Francisco hardware store owner, success will depend on understanding these global dynamics, building strategic relationships, and continuously evolving business strategies that embrace the complexity of international production networks.RELATED NEWS

Business

Tech Titan's Turbulence: IBM Braces for Fiscal Headwinds and Economic Uncertainty

2025-04-24 11:11:32

Business

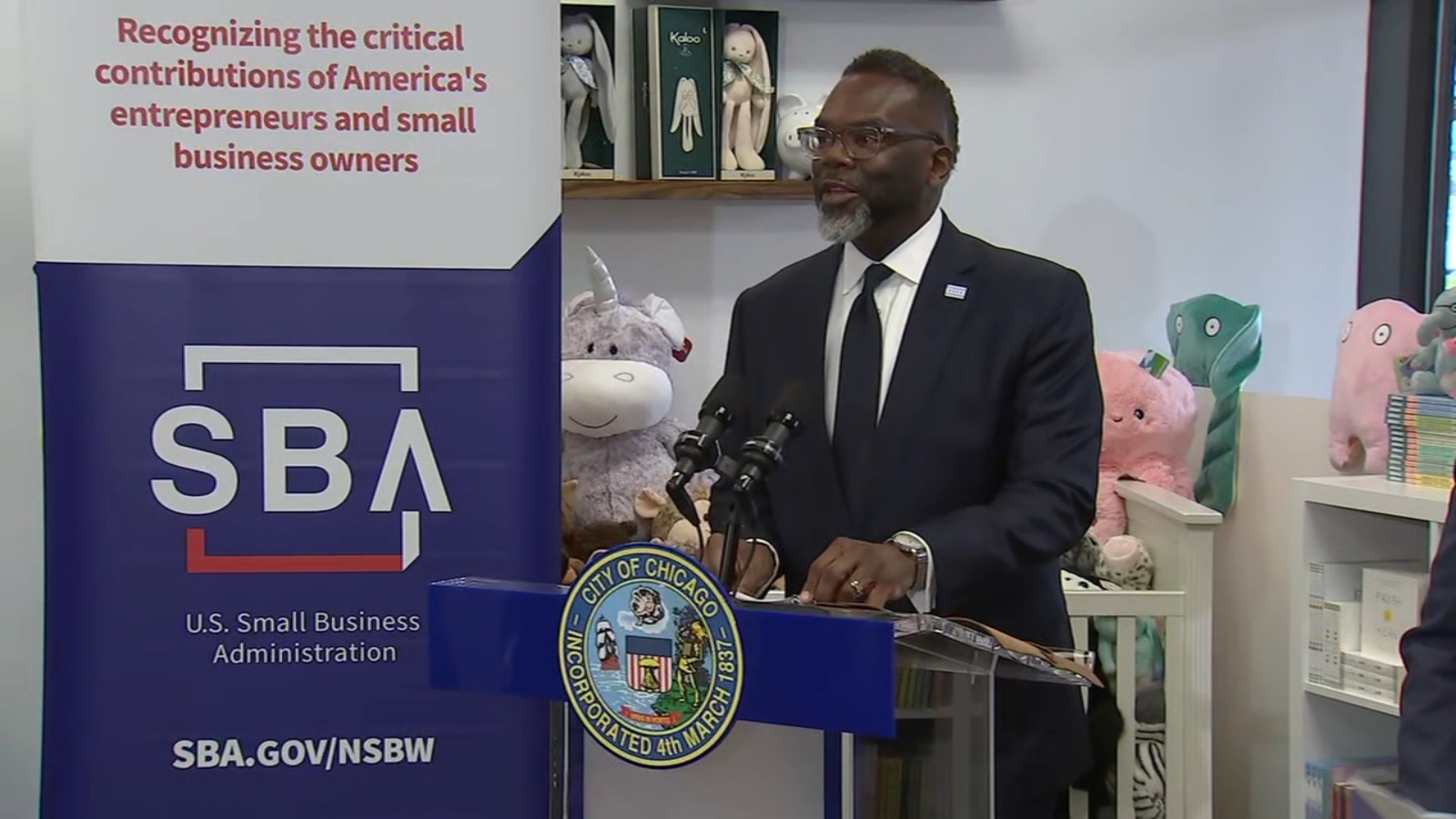

Entrepreneurs Converge: Small Business Week Ignites Innovation in the Windy City

2025-05-05 14:38:00

Business

Mukesh Ambani's Satellite Gambit: How India's Tycoon Is Supercharging Starlink's Global Ambitions

2025-03-12 10:03:27